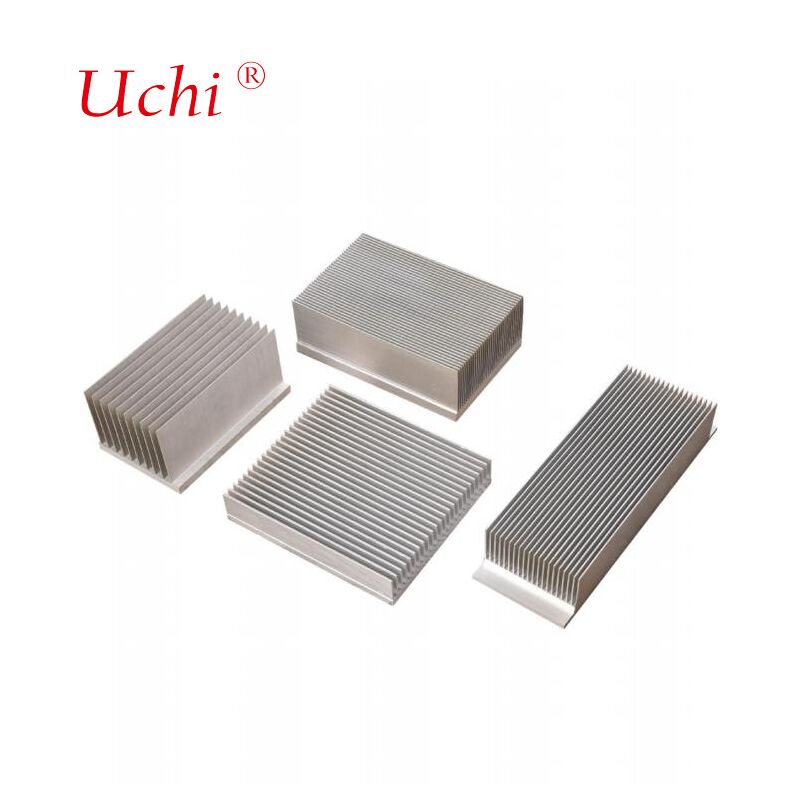

Alloy Aluminium Skived Fin Heat Sink Untuk CPU Cooling

Detail produk:

| Tempat asal: | Dongguan , Guangdong, Cina |

| Nama merek: | Uchi |

| Sertifikasi: | SMC |

| Nomor model: | pendingin sirip skived 01 |

Syarat-syarat pembayaran & pengiriman:

| Kuantitas min Order: | 100 buah |

|---|---|

| Harga: | dapat dinegosiasikan |

| Syarat-syarat pembayaran: | T/T,paypal,Western Union,MoneyGram |

| Menyediakan kemampuan: | 50000000pcs per bulan |

|

Informasi Detail |

|||

| Nilai: | Seri 6000 | Layanan Pemrosesan: | Memotong, Meninju, Decoiling, Membungkuk, mengebor |

|---|---|---|---|

| Melunakkan: | T3 ~ T8 | Sedang mengemas: | Karton TAS PE |

| Toleransi: | ±1% | Standar: | Heatsink aluminium berkualitas menengah dan tinggi |

| Proses yang dalam: | Pemesinan Cnc | Bahan: | Aluminium 6063 |

| Menyoroti: | pemanas panas CPU aluminium,Piring pendingin sirip skived,pemanas panas paduan untuk CPU |

||

Deskripsi Produk

Alloy Aluminium Skived Fin Heat Sink Untuk CPU Cooling

Heatsink aluminium yang dapat disesuaikan terbuat dari paduan 6063 berkualitas tinggi, dengan pemesinan CNC yang tepat dan perawatan permukaan anodisasi untuk aplikasi dalam pencahayaan LED, elektronik,dan peralatan pasokan listrik. Menawarkan toleransi ± 1% dan layanan pemrosesan serbaguna termasuk ekstrusi, pemotongan, dan pengeboran.

| Bahan | Aluminium 6063, 6061, dll Terima kustomisasi |

|---|---|

| Ukuran | Menerima kustomisasi |

| Warna | Hitam, Perak, menerima kustomisasi |

| Pengaturan khusus | Lubang Bor, Pencetakan Serat Sutra, CNC dll. |

| Menggambar | PDF, 3D, CAD, JPG dll. |

| Pengolahan Permukaan | Anodizing, Sand Blasting, Painting, Chromating dan Laser Marking |

| Layanan Pengolahan | Profil Ekstrusi - Pemotongan - Mesin CNC - Pengeboran - Pengetikan - Pengeboran - Pembersihan - Pemeriksaan - Pengemasan |

| Aplikasi | Pencahayaan LED, Inverter, Peralatan Listrik Rumah Tangga, Mesin Las, Perangkat Komunikasi, Peralatan Pasokan Listrik, Industri Elektronik, Pendinginan/Generator Termoelektrik, dll. |

Aplikasi dalam Manufaktur High-End

Produksi Semikonduktor dan Chip

Teknologi kemasan canggih (misalnya, penumpuk 3D) menyebabkan akumulasi panas di dalam chip, di mana konduktivitas termal bahan tradisional telah menjadi kemacetan.

AI Computing/Data Center

Dengan meningkatnya kepadatan arus panas dari chip, metode pendinginan tradisional berjuang untuk memenuhi permintaan,Membuat manajemen termal sebagai "tepi tak terlihat" yang membatasi peningkatan daya komputasi.

Perlengkapan udara

Lingkungan luar angkasa memiliki suhu ekstrim dan vakum tinggi, di mana disipasi panas konvektif tidak mungkin. Akibatnya, peralatan aerospace terkena fluktuasi suhu yang keras.

Aplikasi dalam Kehidupan Sehari-hari

Perangkat Digital

Modul disipasi panas internal yang terdiri dari sirip pendingin logam dipasang di komputer, ponsel, konsol game dan perangkat lainnya untuk memastikan kinerja yang berkelanjutan.

Perangkat Komunikasi

Untuk menjamin stabilitas transmisi dan pemrosesan data berkecepatan tinggi, perangkat-perangkat ini biasanya dilengkapi dengan heat sinks besar.

Peralatan Rumah Tangga

Kompresor dan kondensor unit eksternal membutuhkan kinerja disipasi panas yang efisien, karena mereka terus mentransfer panas dari ruang dalam ke ruangan.

Perangkat pencahayaan

Desain disipasi panas yang efisien memastikan efisiensi cahaya dan umur panjang lampu LED;realisasi penghematan energi tidak dapat dipisahkan dari dukungan teknologi disipasi panas.

Kendaraan Energi Baru

Kendaraan energi baru membutuhkan sistem pendingin cair yang canggih untuk mempertahankan suhu operasi yang optimal.

Titik Kesakitan di Industri Manufaktur Penyebaran Panas Tradisional

- Teknologi pendingin udara tradisional tidak lagi mampu memenuhi permintaan kepadatan fluks panas lebih dari 50W/cm2 untuk prosesor berkinerja tinggi seperti chip AI.

- Kinerja bahan konduktif termal telah mencapai kemacetan, dan koefisien konduktivitas termal lemak termal konvensional sulit melebihi 5W/m*K.

- Meskipun teknologi pendinginan cair memberikan kinerja yang superior, ia memiliki proses produksi yang kompleks dan persyaratan teknis yang tinggi.

Transformasi dan Peningkatan Produk

Industri disipasi panas sedang mengalami transformasi strategis dari industri pendukung menjadi sektor teknologi inti utama.

- Dalam hal teknologi, ia beralih dari disipasi panas seragam ke kontrol suhu presisi, dengan teknologi pendinginan cair muncul sebagai solusi arus utama

- Dalam hal posisi industri, ia berubah dari produsen menjadi penyedia solusi "penyemburan panas sebagai layanan"

- Dalam hal sistem material, itu berkembang menuju konduktivitas termal yang tinggi dan kecerdasan

- Dalam hal paradigma manufaktur, ia secara mendalam mengintegrasikan digitalisasi dan manufaktur aditif

Pada dasarnya, transformasi ini adalah revolusi identitas dari proses tambahan ke desain terkemuka.Kapasitas disipasi panas telah menjadi salah satu indikator inti untuk mengukur daya saing ekonomi digital.

Keuntungan Perusahaan

Lokakarya cetakan dilengkapi dengan 22 set mesin pelepasan listrik (EDM) dari berbagai jenis, termasuk 2 mesin EDM cermin MAKINO.di antaranya 3 adalah mesin EDM pemotong kawat Seibu dan 1 adalah mesin EDM pemotong kawat Sodick yang diimpor dari JepangSelain itu, bengkel ini dilengkapi dengan 7 mesin erosi percikan, 10 mesin penggiling, 2 mesin penggiling dan 1 mesin bubut.

Kemampuan Peralatan & Hardware yang Kuat:

- Ukuran meja: 500×350 mm

- Kecepatan kecepatan cepat: 5000 mm/menit

- Berat maksimum benda kerja: 500 kg

- Berat elektroda maksimum: 50 kg

Keakuratan Mesin Tinggi:

Mengadopsi teknologi baru SuperSpark4 dan IES (Intelligent Expert System),Kami menyediakan pasokan listrik adaptif canggih dan kontrol lompatan untuk menstabilkan proses EDM dan meningkatkan presisi mesin secara bersamaanDilengkapi dengan teknologi ultra-surface dan generator ultra-edge yang canggih, bengkel ini mampu mencapai finishing permukaan dan kualitas metalurgi yang sangat baik.

Aplikasi Produk

Penjaminan Mutu

Kami mempertahankan standar kualitas yang ketat dengan peralatan pengujian yang komprehensif termasuk:

- 1 Mesin Pengukur Koordinat

- 1 instrumen proyektor

- 2 mesin pengujian tekanan tinggi air

- 4 mesin pengujian resistensi termal

- 2 mesin pengujian kebocoran cairan

Komitmen Layanan Pelanggan

- Tanggapan cepat untuk semua pertanyaan

- Harga kompetitif dengan kualitas terjamin

- Penjadwalan produksi yang efisien

- Solusi transportasi yang optimal

- Dukungan teknis yang komprehensif

Pertanyaan yang Sering Diajukan

Apakah Anda perusahaan dagang atau produsen?

Kami adalah produsen profesional pemanas panas dan lempeng pendingin air dengan pengalaman yang luas dan tim teknis yang kuat, menampilkan produksi otomatis dan mekanis.

Apakah Anda telah mengekspor barang sebelumnya dan ke wilayah mana?

60% dari total produksi kami diekspor ke Jepang, India, Inggris, Kanada, AS, dan Brasil.

Berapa banyak karyawan yang Anda miliki?

Sekitar 100 karyawan di seluruh departemen penjualan, pembelian, teknik, QA, gudang, dan produksi.

Bisakah kau memberikan sampel jika kami setuju dengan desainnya?

Ya, kami menyediakan sampel untuk konfirmasi sebelum produksi massal, bersama dengan gambar teknis jika diperlukan.

Metode kemasan apa yang kamu gunakan?

Kemasan yang disesuaikan dengan karton normal dan kain tahan kekakuan atau karton kayu untuk perlindungan optimal selama transportasi.

Apakah Anda memberikan dukungan teknis untuk masalah produk?

Semua produk diperiksa sepenuhnya sebelum pengiriman. Untuk masalah apapun, kami memberikan solusi teknis segera.

Ingin Tahu lebih detail tentang produk ini